Govt to Fund 75% of Fab Costs as India’s First Chips Roll Out

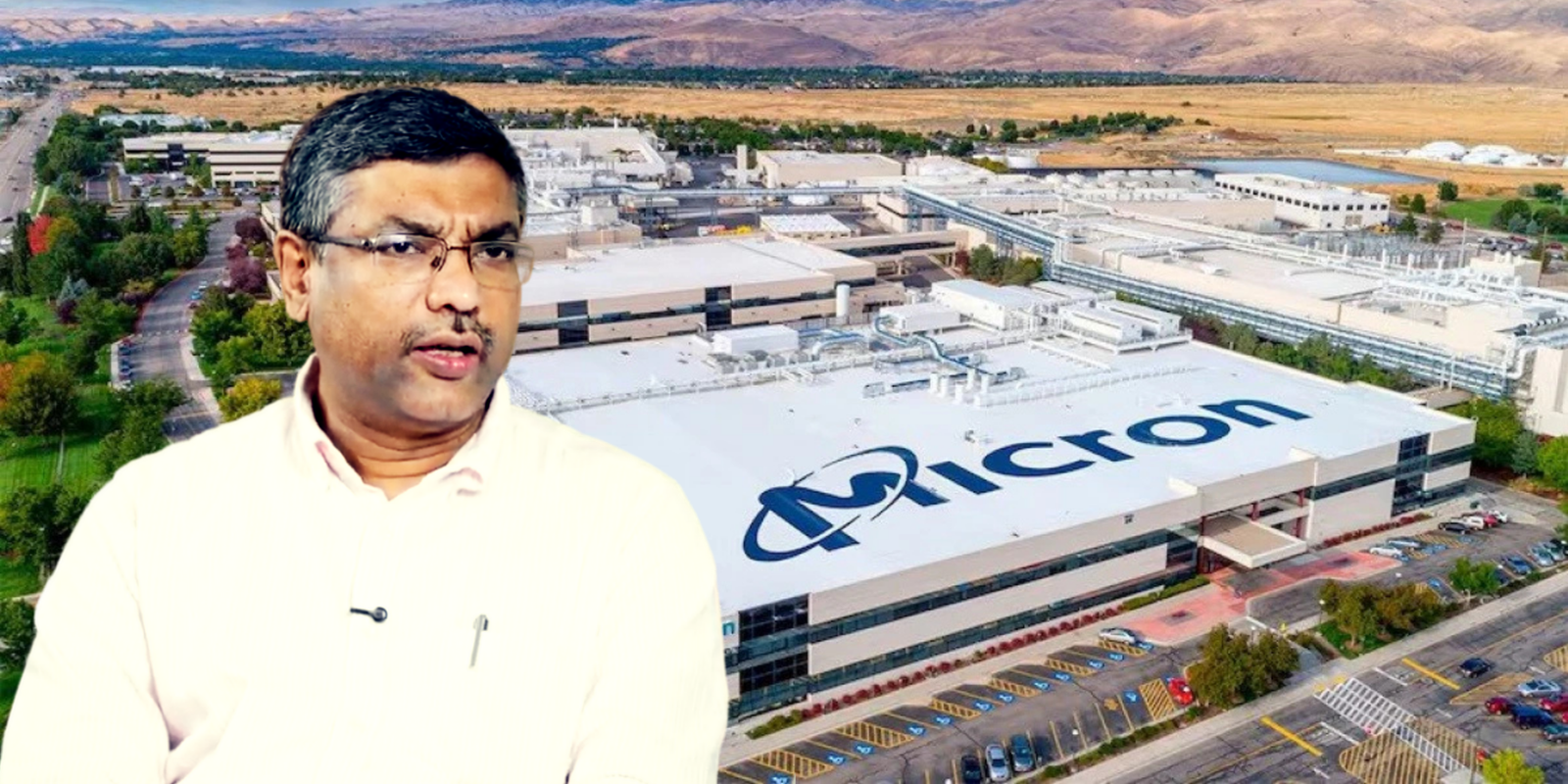

“This is a significant milestone,” said Mr. S. Krishnan, Secretary, Ministry of Electronics and IT (MeitY). “The first purely India-made chips have rolled out, and the foundation is now set for scaling.”

Govt subsidy covers three-fourths of fab costs

The government is covering up to 75% of fab construction costs through combined central and state support. The Centre contributes 50% while states add another 25%. Crucially, subsidies are released during construction rather than after completion.

“This is probably the most generous industrial policy programme ever undertaken in India,” Mr. Krishnan said, adding that nearly Rs 76,000 crore ($10 billion) has already been committed.

He explained that, unlike in the past, when India could not afford such large-scale subsidies, current policy reflects both economic capacity and the strategic need to enter semiconductors.

Lessons from the past and why India lagged

India’s semiconductor story dates back to the Semiconductor Laboratory (SCL) in Mohali, set up in the 1960s. While the lab supplied chips for space missions and ISRO projects, it failed to take off commercially.

According to Mr. Krishnan, the reasons were clear: “Advanced manufacturing requires heavy subsidies, and as a developing country at the time, India had to prioritise other bets.” This time, with adequate funding and global supply chain shifts, India is positioned differently.

Positioning in the global race

Industry observers often compare India’s starting point to an SUV racing against Formula One competitors like Taiwan, South Korea, Japan, and the US. Mr. Krishnan acknowledged the gap but said India is making deliberate choices.

“We have chosen mature nodes between 28nm and 110nm. These are proven, cost-effective technologies with wide applications in autos, electronics, and home appliances,” he explained. “It is better to establish a strong base before attempting high-risk advanced nodes.”

Employment and ecosystem impact

While large fabs are highly automated and will not create millions of jobs directly, the ecosystem around them will generate opportunities in logistics, ancillary units, and services.

Mr. Krishnan stressed that the real employment potential lies in semiconductor design, where India already contributes 20% of the global talent pool. “Our design engineers create IP worth billions, but much of it is held abroad. Our mission is to bring more of that IP ownership back to India,” he said.

Political consensus and execution

Reflecting on the pace of progress, Mr. Krishnan credited political consensus and strong leadership. “Civil servants can only do so much. What matters is leadership that gives us space to act. In semiconductors, we’ve had that clarity and support,” he said.

A pivotal moment for India

With subsidies covering most of the investment, chips already rolling out, and major fabs under construction in Gujarat, India is no longer on the sidelines. “Semiconductors are a foundational industry. You cannot afford not to be there,” Mr. Krishnan said. “This is the start of India’s journey to secure its place in the global supply chain.”

Discover more from News Hub

Subscribe to get the latest posts sent to your email.