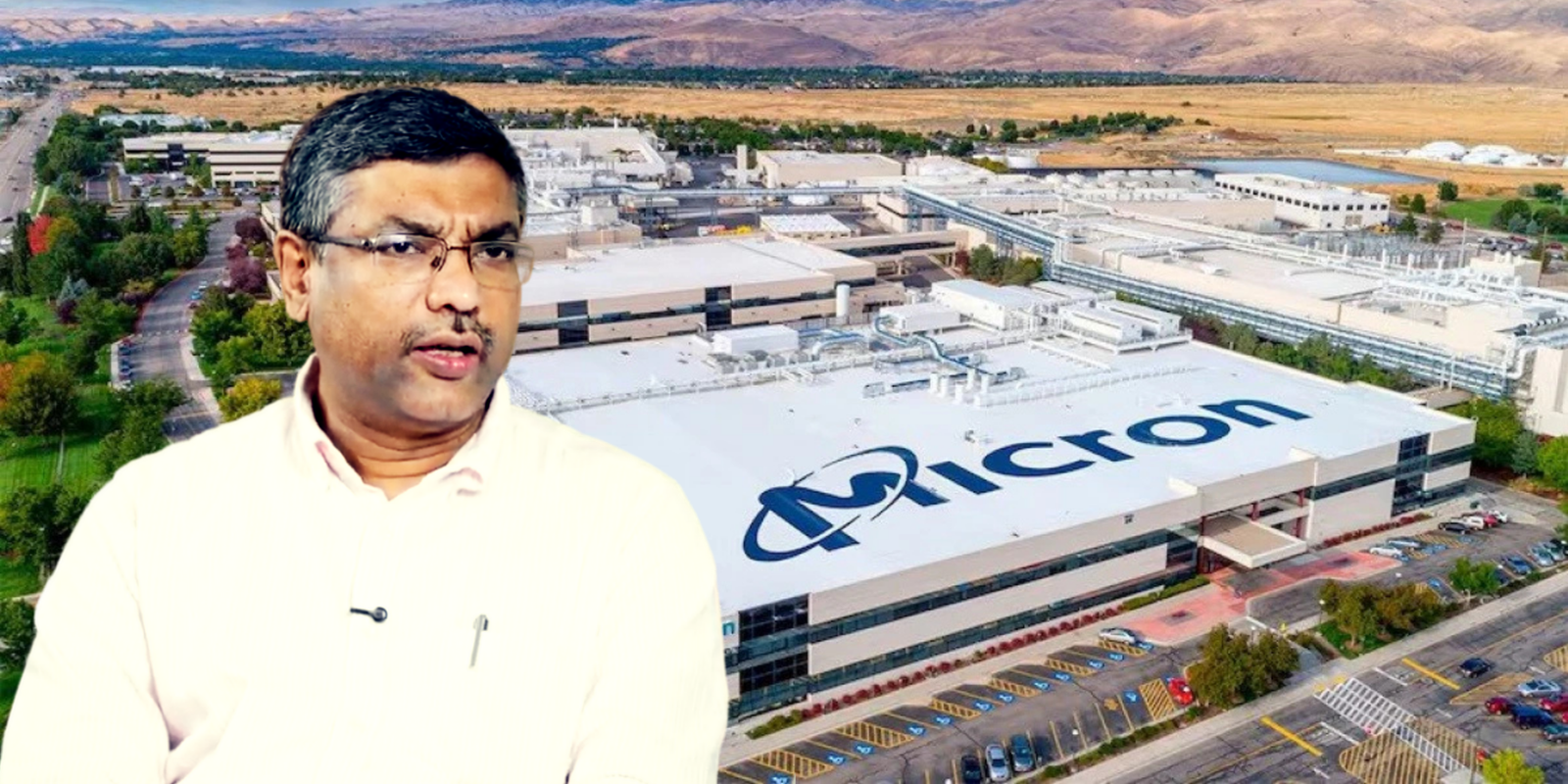

India’s First Chip Pilot Plant Opens in Sanand; Micron Fab Nears 2025

Speaking on the development, Mr. S. Krishnan, Secretary, Ministry of Electronics and IT (MeitY), said, “The first purely India-made chips have already rolled out. We are at a stage where the mission’s primary goals are being realised.”

Micron fab on track for 2025 launch

Alongside the pilot, construction is advancing on Micron Technology’s large-scale semiconductor fab in Sanand, which Mr. Krishnan confirmed is expected to be commissioned by late 2025. The Micron facility will be India’s first major high-volume semiconductor plant, positioning the country on the global chip map.

Other approved projects include Tata Electronics’ initiatives and CG Power’s facilities, all sanctioned within the last two years. In total, 10 semiconductor projects have been approved under the India Semiconductor Mission since its launch.

Subsidies designed for speed and scale

Mr. Krishnan explained that India’s industrial support programme is unprecedented. The Government of India provides a 50% subsidy, while state governments contribute another 25%, meaning up to 75% of fab costs are covered.

What makes the scheme distinct is its real-time disbursal of subsidies, which are released during construction rather than only after completion. “This is probably the most generous government industrial policy programme ever undertaken in India,” Mr. Krishnan noted. So far, nearly Rs 76,000 crore ($10 billion) has been committed.

Focusing on mature nodes to build a strong base

Unlike the US or Japan, which are targeting 2nm to 12nm chips, India is beginning with mature nodes between 28nm and 110nm. Mr. Krishnan said the decision was deliberate: “For a country just beginning in this sector, it is better to succeed with well-established technologies than take a very risky bet on cutting-edge nodes.”

These mature chips power automobiles, consumer electronics, and home appliances, sectors that guarantee steady demand in India’s domestic market. This ensures India’s fabs will have immediate applications while building the expertise to later expand into advanced nodes.

Clusters, ecosystems, and design-led IP

To maximise impact, India is replicating global best practices by building semiconductor clusters. Sanand and Dholera in Gujarat are emerging as hubs, supported by R&D institutions and state incentives.

At the same time, India’s semiconductor design ecosystem—already employing 20% of the world’s design engineers—is being strengthened through the Design-Linked Incentive (DLI) scheme and the Chips to Startup programme. These schemes provide funding up to Rs 50 crore and access to expensive EDA tools from companies like Cadence and Synopsys.

Mr. Krishnan highlighted that startups, including those in Kerala working on RISC-V open-source chip architectures with support from IIT Madras and C-DAC Trivandrum, are key to building domestic intellectual property (IP).

.thumbnailWrapper{

width:6.62rem !important;

}

.alsoReadTitleImage{

min-width: 81px !important;

min-height: 81px !important;

}

.alsoReadMainTitleText{

font-size: 14px !important;

line-height: 20px !important;

}

.alsoReadHeadText{

font-size: 24px !important;

line-height: 20px !important;

}

}

India enters the global semiconductor race

While India is decades behind established hubs like Taiwan or South Korea, Mr. Krishnan stressed that the foundations are now in place. With the Sanand pilot already producing chips and Micron’s fab on the way, India is no longer a spectator but a participant in the global chip race.

“The semiconductor industry is foundational. It powers everything from appliances to automobiles to electronics. We have to be there,” he said. With political consensus, unprecedented subsidies, and early successes, India is poised to build a sustainable semiconductor ecosystem that blends manufacturing strength with design-led innovation.

Discover more from News Hub

Subscribe to get the latest posts sent to your email.